AIRCRAFT AND AEROSPACE

|

|

|

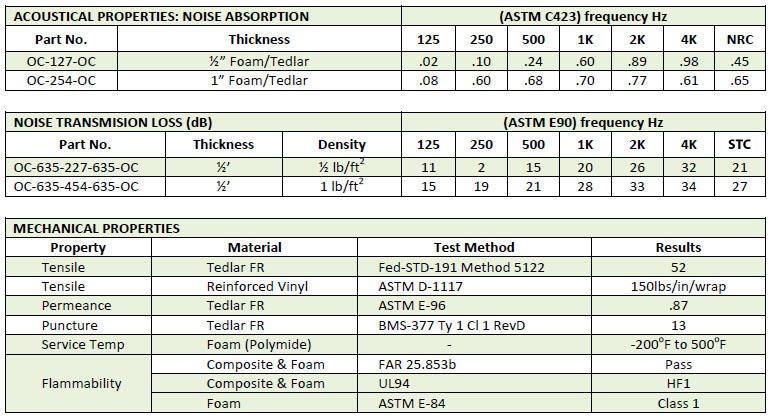

AIRFRAME & HEADLINERS – O’Neill Industrial Corp. has been fabricating airframe acoustical blankets for over 30 years. Manufacturing to customers drawings and providing acoustical kits for production lines are strengths O’Neill Industrial Corporation has developed from years of experience. FEATURES: |

AIRFRAME & BATTINGS –Whether the demand is for: airframe batting noise absorption behind trim panels; extensional damping trim panels; or mass loaded noise barrier blankets, we have the materials, equipment and personnel to meet the need. FEATURES: |

COPYRIGHT 2014 O’NEILL INDUSTRIAL CORPORATION

NOTE: All date about the products listed in this brochure are based upon tests conducted with specific materials, installed as stated, and tested with conventional instruments under ambient conditions. This information, therefore, may be considered as being indicative of representative properties and characteristics performance obtainable. However, since environmental and/or installation conditions vary, we make no warranty, express or implied, concerning use of these products, nor do we accept responsibility for any misapplication of these products.